Armor Meca Développement Presentation

Our trades

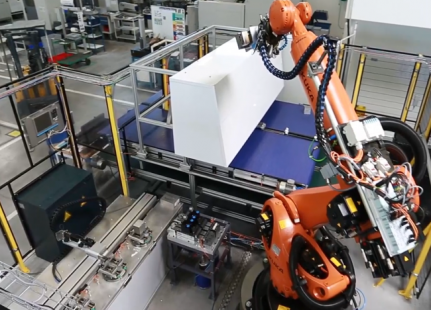

Armor Meca serves its clients to provide increasingly effective solutions, seeking continual optimisation. Armor Meca has established specific organisation methods for each of its trades to reduce cycle times.

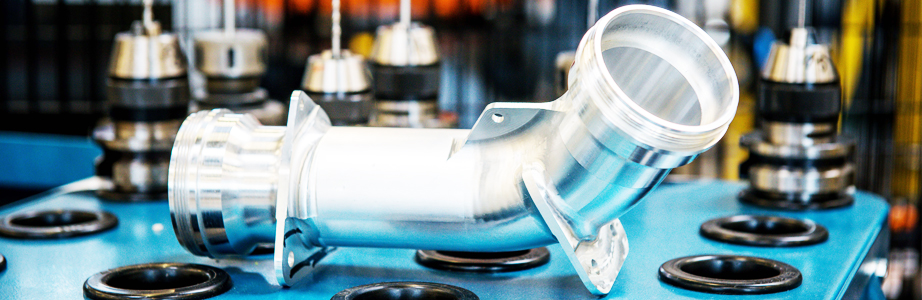

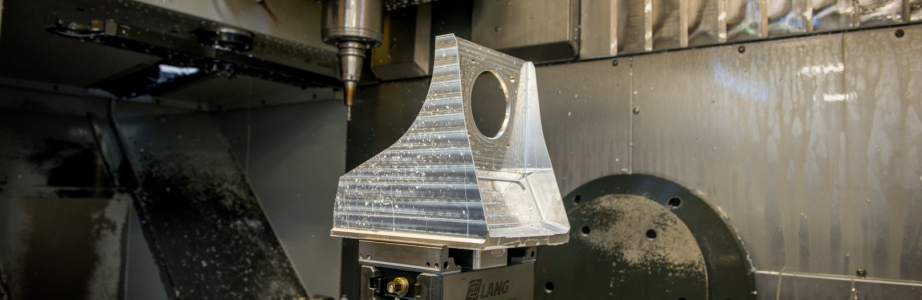

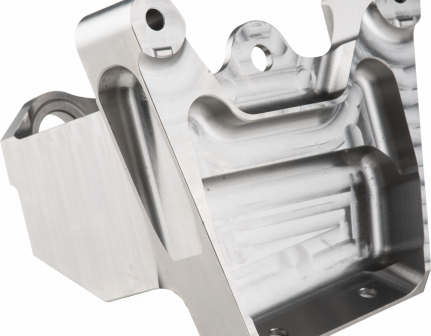

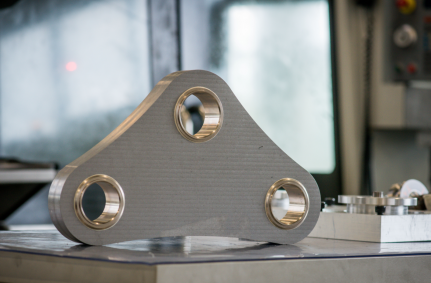

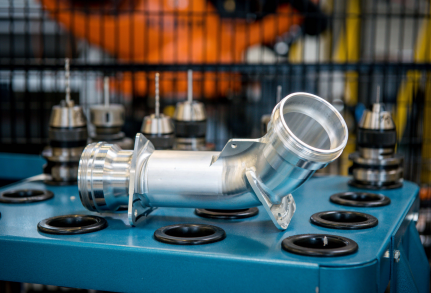

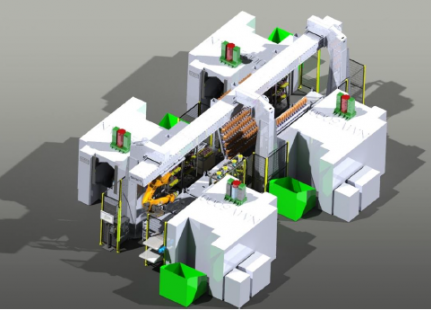

Machining

We are experts in machining complex and highly critical parts in aluminium, titanium, stainless steel and super alloys. With 50 years of experience and customer-focused expertise, we continuously optimise our machinery through a policy of sustained investment, which in 2017 allowed us to count more than 60 recent machines, including 75% digitally-controlled 5-axis machines.

Assembly

Design-to-cost

Design office

![]()

ARMOR MECA

ZI La Grignardais

22490 Pleslin-Trigavou

![]()

Follow us on social networks